What is a Roof Coating?

So what exactly does the term roof coating mean in today’s time? A roof coating is a monolithic, fully adhered, fluid-applied roofing membrane. The most common roof coatings in the market today are elastomeric, meaning that the coating has elastic properties that allow it to stretch and return to the original shape without damage. Roof coatings are particularly important in climate zones that experience dramatic weather conditions.

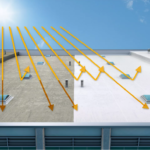

This roof coating is considered the top layer of a composite roof membrane and underlying system. Roof coatings act as the first line of defense against the impact of sunlight (both infrared and ultraviolet (UV)), rain, hail, and physical damage. The process of installation is referred to as cold-process.

Tested Through the Ages

It may surprise many to hear that cold-process coatings date back to at least the year 3000 BC. Archeologists have discovered that early Egyptian architecture used varnishes and enamels made of beeswax, gelatin, and clay on their roofs. Additionally, a protective coating made of pitch and balsam was used to waterproof their wooden boats. It is believed that the Egyptians created varnishes from gum Arabic as early as 1000 BC.

Beyond the shores of the Niles, ancient Asian architects were using lacquers and varnishes by the 2nd century BC. It was common for buildings to have these liquid coverings throughout China, Japan, and Korea. Even the Early Greeks and Romans applied coatings to provide protection and artistic style to their homes, ships, and artwork.

Historical dwellings in Europe, Asia, and the Americas were constructed with various cold-applied mixtures of clay, soil, and water, as well as stucco pastes of water, sand, and limestone or gypsum to waterproof their roofs and walls. (RCMA) We can still see many of these early coating materials being used today.

Technology Advancement

With roof coatings having such a long history, it is essential to understand the significant technological development they have gone through. To appreciate the sophisticated protective coatings available in today’s market, we must travel back to the 17th century. In the latter half of the 17th century, a German chemist experimented with coal tar as a protective coating on woods and ropes. In the 19th and early 20th centuries, scientists began to use new organic, inorganic, and synthetic materials in coatings, binders, and solvents. During this period, contractors would soak rag felt in tar (pine tar or coal tar), layered these felts with moppings of hot tar, and covered the assembly with gravel. The tar was eventually (mostly) replaced by asphalt, and the rag felt with fiberglass mat to create the modern Built-Up Roof (BUR). (RCMA)

This practice was the primary way roofing contractors installed roofs for the better part of a century. If a low-slope roof was called for, the hot-applied Built-Up Roof was the only choice. It was not until the middle part of the 20th-century scientists made the most significant advancement to roofing materials by incorporating emulsion polymers.

Not all polymers that are used to make adhesives are interchangeable. A chemist experiments with each kind of polymer and comes to understand each one’s best use. This is why you don’t see elastomeric roof coatings advertised as a leather tanning material. Interestingly enough, a well-known product, Plexiglas, is created from polymers and is known for its ability to withstand impact. It is often used in banks to provide a bulletproof shield and has been very popular this past year as a germ shield. It would seem ridiculous to use this product on a roof because it would not meet the reflectivity requirement, withstand the elements over time, and is not malleable.

Acrylic polymer can also be manufactured into paint, adhesive, or caulking. In the 1950s, scientists found that these acrylic polymers provided better adhesion to roof substrates. The specific polymer had low-temperature flexibility, was tear-resistant, had minimal water absorption, and proved dirt-resistant. In the 1970s, technology advanced enough to where acrylic polymers were incorporated into a waterborne emulsion. This was when acrylic latex waterborne house paints were created. This house paint is now the most widely used, highly durable house paint material on the market. Some manufactures have tried to use house paint on roofs. Although it does provide reflectivity, it is not durable over time and ultimately becomes brittle and chalky.

As the understanding and use of acrylic polymers evolved, manufacturers made significant advancements to these original paint formulas, making it possible to create durable and reflective roof coatings. These products have become so trusted that over the past 40 years, contractors have shifted from using hot asphalt and roofing kettles to cold-applied processes. Here at GC Roofing, we have built an entire roofing company on these products. We have been installing these kinds of roofs since the 1980s and are confident that they can be an excellent solution for your roofing needs.

References

American Weatherstar. (2020) Roof Coating 101. Retrieved from https://www.americanweatherstar.com/roof-coatings-101/

National Coatings. (2020) Acrylic Roof Coatings 101. Retrieved from https://www.nationalcoatings.com/acrylic-roof-coatings-101

Roof Coatings Manufacturers Association (RCMA), 2020, History of Roof Coatings. Retrieved from https://www.roofcoatings.org/history-of-roof-coatings/#:~:text=The%20use%20of%20cold%2Dprocess,to%20waterproof%20their%20wooden%20boats.&text=Many%20of%20these%20early%20coating,in%20the%20coatings%20of%20today.